Process Changes with Growth

9 March 2020

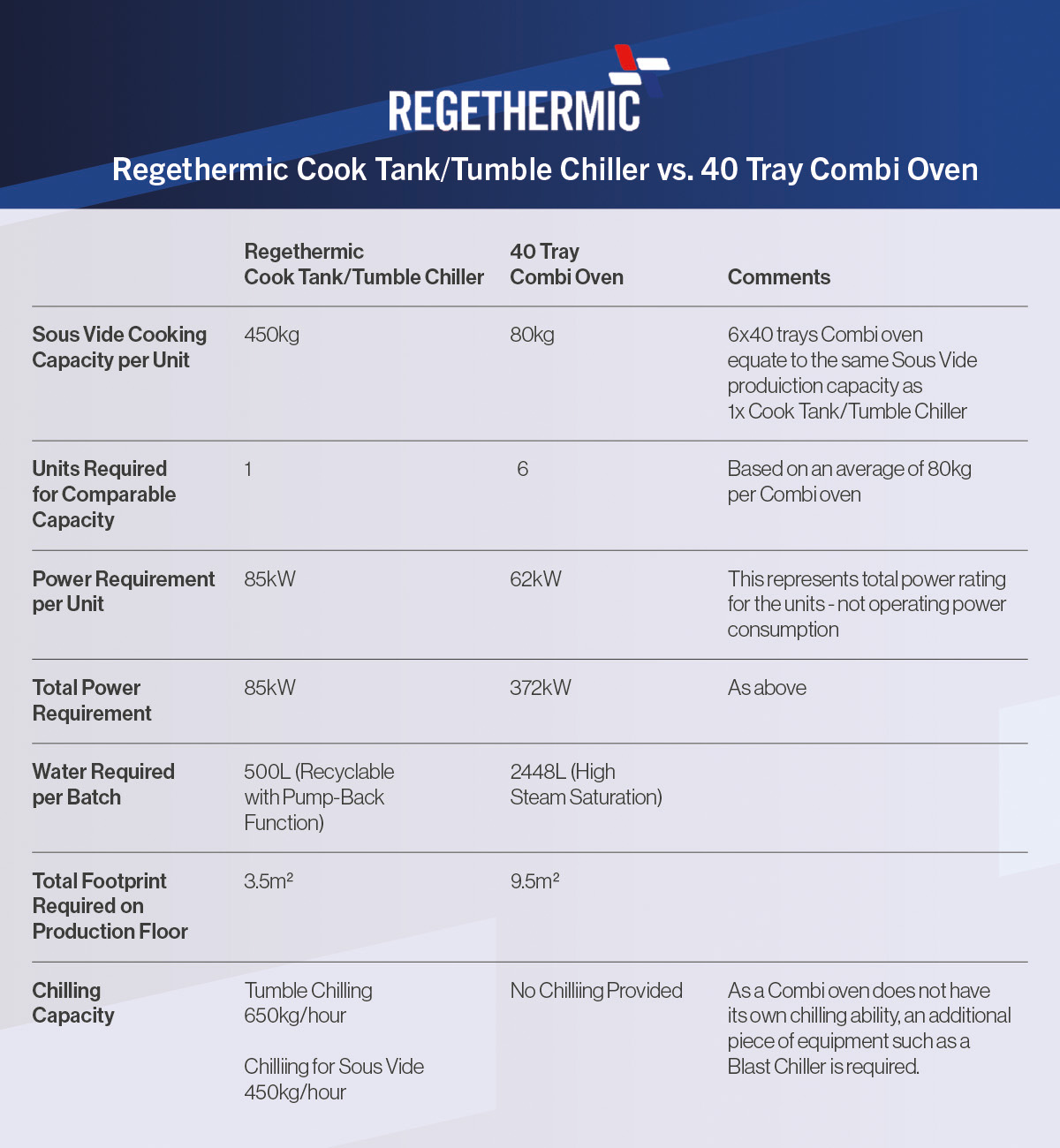

I once had a customer who, every year, would purchase an additional 40 tray Combi oven to cope with his growing business. It wasn’t long before his production facility was cramped with 14 x 40 tray Combi ovens. I love what a Combi oven offers chefs as far as flexibility and functionality. However, as your business expands and faces the dilemma of achieving greater efficiency while still operating within the same production facility, the Regethermic Cook Tank / Tumble Chiller becomes a tailored solution for the larger scale operations you aspire to. With automated sous vide and chilling requirements, my above customer could have bought one Regethermic Cook Tank / Tumble Chiller in place of 6 Combi ovens.

Check out the comparison table below to consider the best solution for your growing needs:

Sous vide production in the Cook-Tank / Tumble Chiller:

- Water is 23 times more efficient at thermal transfer than air so offers a considerable better medium of both heating and cooling

The Cook-Tank / Tumble Chiller offers the following advantages:

- 3 points of temperature validation to ensure all correct temperature of cooking and pasteurisation are met

- Automatically cooks, pasteurises and chills the product

- Offers a pump-back function to greatly reduce water consumption

- Has the ability to tumble-chill bagged product

- Monitors and records all HACCP information

- Has a tumble cook function for product such as pulled beef or pork

Click here to see the video of the Cook Tank/Tumble Chiller in action.